TEL:0594-5330133

Company tenet: customer first, quality first, safe production, energy saving and high efficiency

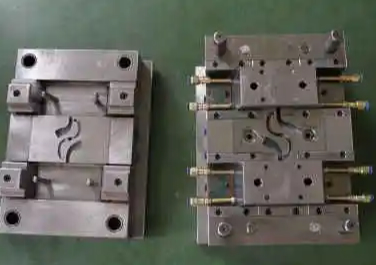

In order to effectively maintain the precision of the mold, extend its service life, stabilize the production operation, ensure the quality of the molded products, and reduce the occurrence of faults in the production process, the company provides a mold maintenance reference scheme for customers' reference. This scheme is applicable to all mold maintenance.

Specific content:

1. Mold maintenance is divided into daily inspection and maintenance and regular maintenance in the production process.

2. For daily maintenance, the mold maintainer shall regularly inspect the molds in production and make maintenance records.

3. The regular maintenance takes the mold from the mold to the end of the production order as a cycle, and the mold maintainer will maintain the mold and make maintenance records.

Items of mold maintenance and inspection:

1. Whether the guide post and guide sleeve are well lubricated.

2. Whether the mold surface is free of residual debris and dirt.

3. Whether the inclined guide post is well lubricated.

4. Whether the sliding block and chute are well lubricated.

5. Whether the ejector pin spring is in good condition, and whether the ejector pin is accurately reset and lubricated.

6. Whether the mold opener bolts are loose and whether the mold pressing plate bolts are not loose.

7. Whether the opening and closing mold is normal and whether the ejection is abnormal.

8. Whether the surface of the cavity is clean and free of accumulated material, foreign matter and rust inhibitor.

9. Check whether the drain hole and exhaust slot are blocked.

Regular maintenance

1. Clean the guide post and guide sleeve and apply lubricating oil.

2. Clean up the dust and oil on the mold surface and the residual scraps and dirt on the parting surface.

3. Confirm that the ejector pin spring is in good condition, and the ejector pin can be accurately reset and lubricated.

4. The mold opener bolts are not loose.

5. The surface of the cavity shall be cleaned and free of accumulated materials and guide objects, and the antirust agent shall be applied.

6. The exhaust hole and exhaust slot shall be cleaned without blockage.

7. Wipe the periphery of the mold with a rag, and there is no water or rust agent.

8. Anti rust treatment of the mold. After production for more than 6 months, replace the anti rust agent with butter to ensure the long-term storage of the mold.

9. Make the corresponding mold maintenance record log.